Did you know that up to 25% of spray foam insulation installations fail to perform as expected? Despite being one of the most effective insulation materials available, spray foam insulation can develop serious problems when not properly installed.

The popularity of spray foam insulation has grown significantly across Canada, particularly in areas like Vaughan where energy efficiency is a priority for homeowners. However, this

high-performance material requires precise application techniques and conditions to function correctly. When these requirements aren’t met, the consequences can be costly and frustrating.

Many homeowners discover issues only months or years after installation, when problems like shrinkage, moisture accumulation, or ineffective insulation become apparent. By then, the damage is done, and repairs often involve complete removal and reinstallation.

In this expert analysis, we’ll examine the most common reasons spray foam insulation fails, from chemical formulation problems to installation errors by untrained applicators. You’ll learn to identify potential issues before they happen and understand what truly makes the difference between a successful installation and a costly mistake.

Chemical and Structural Weaknesses in Spray Foam Formulation

Spray foam insulation relies on precise chemical reactions to create its insulating properties. Even minor formulation errors can lead to substantial performance issues and potential health hazards for residents.

Incorrect A/B Ratio in Polyurethane Reaction

The foundation of spray foam insulation lies in the chemical reaction between two components: the A-side (isocyanate) and B-side (polyol resin). These components must mix in precise proportions, typically 1:1 by volume. Any deviation creates “off-ratio foam.”

Off-ratio foam fails in multiple ways depending on the imbalance:

- Too much A-side: brittle, dark-colored foam that shrinks and under-expands

- Too much B-side: soft, spongy foam that remains sticky and doesn’t cure properly

These result in poor insulation performance, structural instability, and even foul odors. Causes include incorrect machine settings, improper temperature, equipment wear, and poor material storage.

Low-Quality Blowing Agents and R-Value Degradation

Blowing agents form the cell structure within spray foam. Newer formulations use more

eco-friendly agents, but performance still declines over time as gases escape the foam. This naturally reduces the insulation’s R-value.

Some contractors overpromise R-values that don’t hold up long-term. Using poor-quality blowing agents accelerates this decline, especially in colder climates where insulation matters most.

Inconsistent Cell Structure: Open vs. Closed Cell

Spray foam’s microscopic structure significantly affects its performance:

- Closed-cell foam: ~R-7 per inch, denser, air and vapor barrier

- Open-cell foam: ~R-3.8 per inch, lighter, needs additional vapor barrier

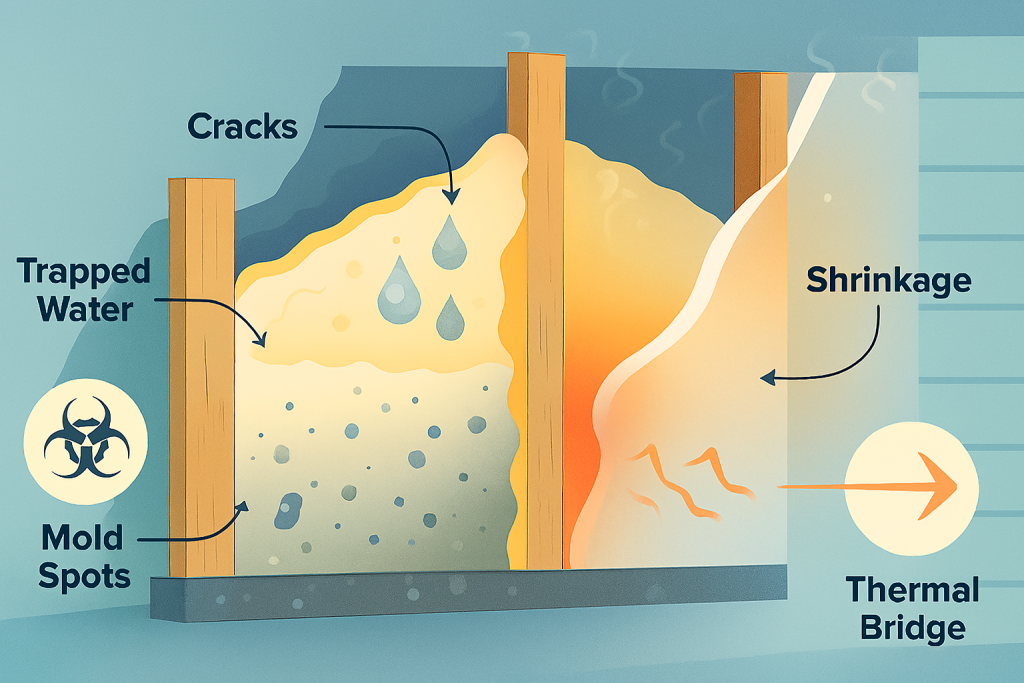

Using the wrong type in the wrong application leads to issues. Open-cell foam without proper vapor barriers can trap moisture and lead to mold. Over-applying closed-cell foam in tight areas can create structural pressure and damage.

Improper Substrate Preparation Before Application

Even with perfect chemicals, spray foam will fail on poorly prepared surfaces. Substrate condition directly affects adhesion and performance.

Moisture Content Causing Separation

Wood must be below 17–19% moisture for spray foam to bond. Hidden moisture or condensation can block adhesion, discolor foam, and weaken its structure. This is a common issue in cold-weather installs where heaters increase ambient humidity. If the surface is below dew point, moisture condenses and ruins adhesion.

Dust and Contaminants on Surfaces

Dust, dirt, oil, or construction residue prevents bonding. Foam might initially stick but later pull away. All surfaces should be cleaned—wood swept, metal degreased, and concrete fully cured before spraying.

A simple rule: if you wouldn’t paint on the surface, don’t spray foam on it either.

Temperature Sensitivity

Ideal surface temperatures range from 40–90°F (5–32°C). Cold surfaces reduce bonding and foam expansion; hot surfaces cause rapid curing and structural defects.

Component temperatures also matter. Foam applied outside the recommended range leads to uneven curing, inconsistent cell structure, and reduced insulation quality.

Common Installation Errors by Untrained Applicators

Installation technique is just as important as formulation. In fact, roughly 40% of failures stem from human error.

Uneven Spray Thickness

Thin spots in foam create thermal bridges—areas where heat escapes. This results in hot/cold spots, higher energy bills, and poor comfort. Missed areas or overly bumpy finishes often fail inspections and reduce the foam’s efficiency.

Overexpansion Stress

Too much foam creates internal heat, causing charring or shrinkage. The pressure of overexpanded foam can warp wood framing, crack drywall, and compromise structural integrity. It also presents a fire risk if not properly sealed.

Poor Spray Distance or Technique

Applying foam too closely or without allowing proper cure time between layers leads to internal heat buildup. This can burn the foam from the inside out. Professional spray technique, including the right distance and cooling time between passes, is essential.

DIY kits and untrained workers often skip these steps, leading to costly mistakes.

Building Code Violations and Oversights

Even when foam appears well installed, violations of building codes and best practices can cause future issues.

Ignoring CAN/ULC S705.2 Installation Standards

This Canadian standard outlines correct spray foam procedures—from chemical selection to application and documentation. Failure to follow it leads to failed inspections, voided warranties, and expensive rework.

Misunderstanding Vapor Barrier Requirements

Closed-cell foam can act as its own vapor barrier—but only at certain thicknesses. If paired with batt insulation, a separate vapor barrier must be added and sealed. Many installs fail to meet vapor barrier standards due to thin foam or lack of continuity.

Unlicensed Installers and Missing Docs

In Ontario, only certified professionals may legally install spray foam. Homeowners should ask for credentials, adherence to installation standards, and full documentation. Improperly trained installers often overlook safety protocols—creating fire hazards or failing inspections down the line.

Post-Installation Failures and Long-Term Degradation

Even well-executed installs can fail over time.

Foam Shrinkage

Shrinkage can create gaps between the foam and studs. In extreme cases, foam width and thickness shrink by over 25–50%. This degrades performance and is hard to detect until major damage occurs.

Moisture Traps and Mold

Spray foam’s air-tight seal can trap humidity and pollutants inside. Without proper ventilation, this leads to:

- Window condensation

- Hidden mold

- Structural rot

These problems often appear after a few seasons, making them difficult and expensive to fix.

Off-Gassing Over Time

Even cured foam may release VOCs over time, especially if disturbed (e.g., drilled into or heated). This poses health risks and reduces indoor air quality.

Conclusion

Spray foam insulation is a powerful tool—but only in the right hands. When installed correctly, it provides outstanding thermal protection, air sealing, and comfort. When done wrong, it leads to expensive failures, structural issues, and even health concerns.

Key takeaways:

- Perfect chemical formulation is critical.

- Surface prep—including moisture, cleanliness, and temperature—is essential.

- Skilled application prevents defects like uneven thickness, overexpansion, and shrinkage.

- Building codes must be followed to avoid compliance issues.

- Long-term issues like shrinkage, mold, and off-gassing should be considered during planning.

Final word: Homeowners should always hire certified, experienced spray foam professionals and ensure their project follows proper protocols from start to finish. The upfront cost of quality workmanship is far less than the price of fixing a failed insulation job.