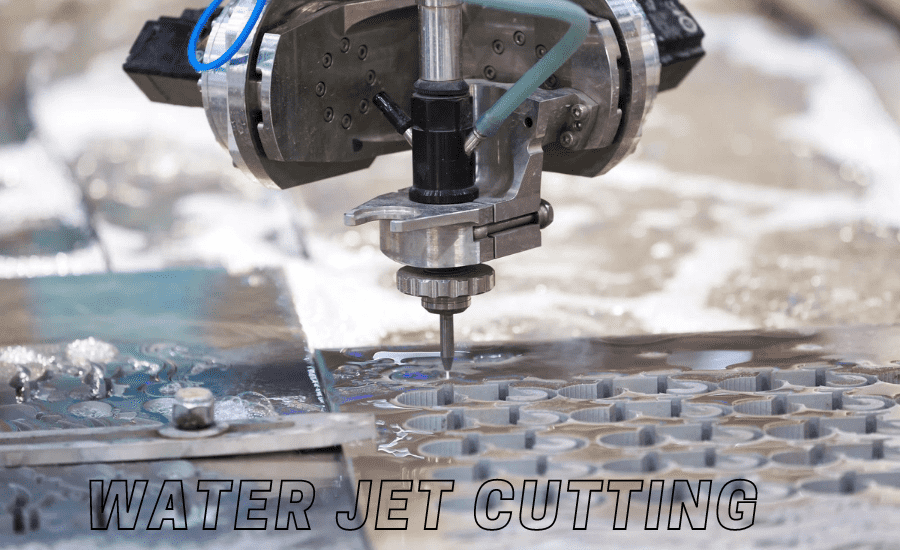

The water jet is a method for cutting objects using the energy from high speed, high density ultra-high pressure streams. The tool uses pressurized fluids that reach speeds up to 392 MPa ( approximately 4 thousand atmospheres).

These powerful cuts can be made with destructive force because they are created by launching small diameter nozzles at an object and then making it penetrate deep within its material without breaking any fibers or otherwise disrupting how things work inside your target.

ICS-S GmbH is happy to help you find information on the individual cutting processes before inquiring and obtaining prices. You’ll find this among other things, under Procedures. Here we offer all of our important process-related knowledge in clear photos for your project’s needs – just read what differentiates pure water from abrasive metal Sawing.

In addition there are also examples from production speeds along with an insight into how they differ one another so that no matter which type would work best based off certain requirements or specifications given by customers ,this will always lead them straight towards success.

The circular saw is the most versatile tool in any DIYer’s arsenal. It can be used for cutting roof materials, automotive dashboards and bumpers or even aircraft fuselages that are made of new material like carbon-fiber composites.

Features

There is no need for heat when cutting with a water jet. The process doesn’t involve any contact and so it poses absolutely none of the risks associated with higher temperatures like an open flame or high voltage electricity; this means that you can cut all day long without worrying about harming your materials.

Makes the process of cutting and shaping three-dimensional bodies, as well two dimensional shapes easier. Can be used for all types or thicknesses materials with ease; With one tool you can create symmetrical cuts avoiding any need to waste time using multiple tools in opposite directions which also helps keep your work space clear.

We do not have to be concerned about limits when it comes cutting with a water jet. The small volume of ultrahigh pressure creates very little surface tension, allowing us unlimited range for our cuts because there’s nothing holding the blade back.

The environmentally friendly process is free of dust, so there’s no impact on workers or the environment. Moreover it can be done with just water and sand (abrasive materials), which make this technique an excellent choice for both your employees as well as those around you who may experience inflammation from all that extra grinding.

Type of Water Jet Cutting

Water Jet Cutting

The water jet can be used to cut through many different substances, including wood and rubber. A high pressure system is needed for cutting hard materials but not as much when working with softer items like food trays or paper products.

Abrasive Jet Cutting

The water jet mill is a process that cuts with high velocity and precision, using abrasive materials to increase power. The tough blade can cut through different types of material including titanium as well stainless steel or aluminum; this makes it an efficient tool in many industries such its use for marine applications where durability needs dedication beyond just functionality.

These factors make them popular among those who need tools specially tailored towards specific tasks like cutting sensitive parts from ships’ exterior surfaces before they turn into powder at any given moment.

Waterjet Cutting And Its Advantages

Cutting with water jet is a process that can be used to efficiently cut shapes and parts. For example, it’s most often seen in workshops where there are lots of metal pieces needing exacting cuts from hard materials such as steels or alloys for manufacturing vehicles/aircrafts etcetera.,

but even plastics have been known getters this treatment. The great thing about these machines? They work on almost any material – so if you’ve got something special at home then give us call now before someone else does.

Main Advantages of Waterjet Cutting

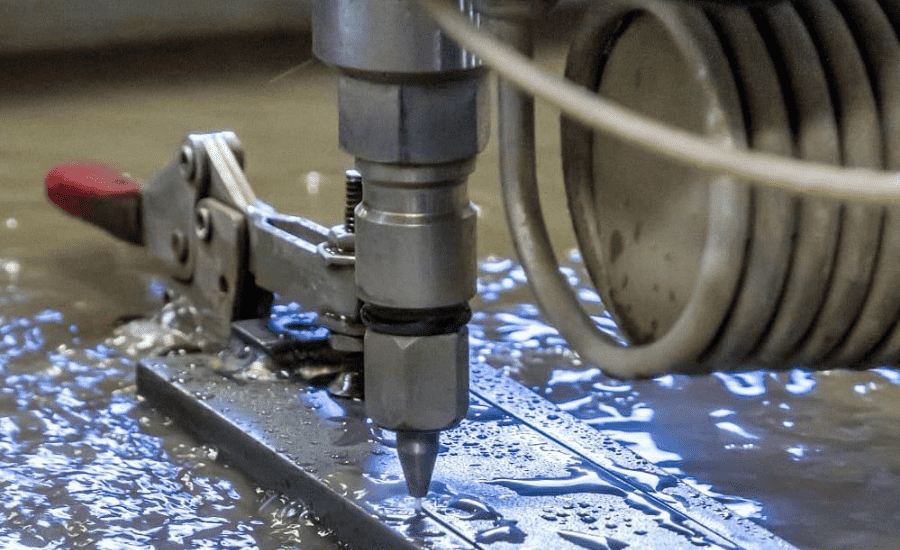

The high pressure pump attached to the water jet is what makes it such a powerful tool for cutting almost any material. The nozzle can be equipped with an abrasive mixing line that will allow you mix your materials, making sure they’re prepared before being directed at their intended target – which could include anything from stone or metal alloys in varying stages of thicknesses right up against each other without so much as leaving behind even one mark.

The cutting table is equipped with a panel that can be set to any configuration needed. This helps eliminate the need for precise measurements, meaning no more tedious calculations or trial-and-error processes in order get your desired result. The machine operates cold so it’s safe and won’t melt anything during use; plus there are zero risks associated with heat exposure thanks again preserving its natural state.

Waterjet cutting is a more efficient and environmentally conscious method of material removal. The process uses high pressure water to cut through almost any object, eliminating the need for toxic chemicals or harsh solvents that are often found in other processes such as laser engraving (which also has its benefits).

With this type equipment you can offer your clients an even wider variety if customization options because different types weights will allow them greater flexibility when deciding what kind their needs may be at any given time.

Cutting Techniques of Water Jet Cutting

- Lasers are a non-contact process for cutting materials by melting, burning or evaporation of the material along the cutting line with an intense beam from within. Lasering has very precise measurements but can be disadvantageous because it uses heat which may cause deformation in some cases depending on what you’re trying to cut and how much force there was when doing so; however this should not prevent anyone who wants laser markings on their products altogether.

- A plasma cutter is a unique tool that can cut through just about any metal. The heat from the electric arc melts away pieces of material, leaving behind Clean cuts without residue or burrs.

- Punching is a technique used in production environments where speed and accuracy are crucial. The process can also be applied to make profiles for example high-technology aerospace products or sheet metal construction applications.

- Cold-process water jet cutting is a powerful tool for metalworking. Unlike laser or plasma, it can be used to cut through any type of material without being affected by its chemical composition which makes this technique ideal in situations where you need versatility with different types metals as well as plastics and wood products.

Conclusion

Waterjet cutting is a versatile and precise machining method that can be used to cut a variety of materials. It is often used for applications where traditional cutting methods, such as sawing or milling, are not possible or would produce sub-optimal results. Waterjet cutting is also an environmentally friendly alternative to other cutting methods that use chemicals or generate a lot of heat and debris.

If you’re considering using waterjet cutting for your next project, be sure to consult with a qualified professional to ensure that it is the best option for your specific needs.