Carbon fiber tapes refers to a flat material made of carbon fiber. It weighs one-seventh as much as steel for a given strength. The carbon fiber core lasts longer than conventional steel cable. The carbon fiber tapes market growth is depend upon various factors including rising usage in aircraft brakes, space structures, and military and commercial planes, rising focus on fuel efficiency, emission reduction, and lightweight construction, among others

In the production of carbon fiber tape, artificial intelligence (AI) is primarily employed to maximize fiber placement and design, pinpoint production flaws, forecast material properties, and track structural health in the finished composite product by evaluating sensor data

Key Growth Drivers and Opportunities

Rising Demand from Aerospace & Defense Sector: In aircraft, carbon fiber straps are widely used due to their remarkable weight-resistance relationship to fatigue resistance. The introduction of carbon fiber composites is accelerated considering the focus on optical materials to improve fuel efficiency and reduce emissions. In addition, defence applications such as UAVs, rockets and body armors are increasingly incorporating carbon fiber tapes to evaluate sensor data, integrate market growth, production errors, and structural health of finished products.

Technological Advancements: Improved manufacturing technologies such as ATL and Automatic Fiber Placement (AFP) have reduced waste and improved production efficiency for carbon fiber adhesive-based components. These innovations make carbon fiber bands accessible and inexpensive, encouraging wider acceptance in the industry.

Challenges

The carbon fiber tapes market growth is disrupted due to their high cost, complex manufacturing and processing techniques, limited recyclability and environmental concerns, any disruption in the supply chain due to geopolitical tensions, export restrictions, or logistics issues can cause price volatility and availability constraints for manufacturers of carbon fiber tapes.

Innovation and Expansion

Toray Partners with Elevated Materials to Repurpose Carbon Fiber Prepreg Waste

In July 2024, Toray Composite Materials America, Inc., a leading manufacturer and supplier of carbon fiber and prepreg materials, announced the execution of a memorandum of understanding (MOU) adding Elevated Materials as a provider of repurposing services for its Tacoma, Washington facility. Under the three-year agreement, Elevated Materials will repurpose Toray scrap prepreg materials, including slit-edge and full-width prepreg sheets.

Toray Develops TORAYCA T1200, the Ultra High-Strength Carbon Fiber

In October 2023, Toray Industries, Inc. announced that it has developed TORAYCA T1200 carbon fiber, the world’s highest strength at 1,160 kilopound per square inch (Ksi). This new offering will move us forward to reducing environmental footprints by lightening carbon-fiber-reinforced plastic materials.

Asahi Kasei collaborates on continuous carbon fiber reclamation development

In January 2023, Asahi Kasei, in collaboration with the National Institute of Technology at Kitakyushu College and the Tokyo University of Science, has developed a new method for recovering carbon fiber from vehicle composites. It enables the fiber to be extracted effortlessly, producing continuous strands with qualities that are identical to those of virgin fiber.

Toray Announces the Launch of Flexible and Highly Adaptive 2700 Prepreg System

On July 20, 2021, Toray Composite Materials America, Inc., a leading innovator and supplier of carbon fiber materials and advanced composite prepreg, announces the launch of Toray 2700. Epoxy-based 2700 is a high-performance, patented resin technology geared toward emerging aerospace programs. It satisfies stringent aerospace structural design drivers and enables the manufacture of high-quality, high-volume, cost-effective composite parts.

Teijin Carbon Europe launches carbon fiber/PPS UD tape

On May 19, 2021, Teijin Carbon Europe announced a new carbon fiber thermoplastic unidirectional pre-impregnated tape (TPUD) based on polyphenylene sulfide (PPS). The new Tenax TPUD with PPS matrix allows entry into new cost-sensitive markets while offering the typical TPUD advantages like resistance to chemicals and solvents, low flammability, storage or shipping at room temperature and recyclability.

About Author:

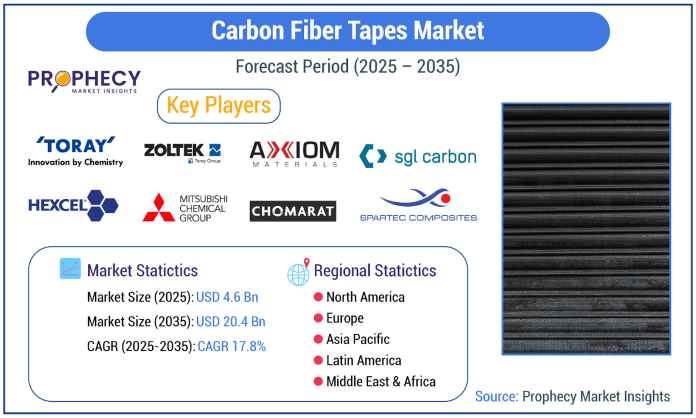

Prophecy is a specialized market research, analytics, marketing and business strategy, and solutions company that offer strategic and tactical support to clients for making well-informed business decisions and to identify and achieve high value opportunities in the target business area. Also, we help our client to address business challenges and provide best possible solutions to overcome them and transform their business.