In the case of rotating machinery and mechanical assemblies, the role of bearing systems is to facilitate smooth, low-friction motion as they support shafts. There are many kinds of bearings (with many different materials) to support shafts in an industrial context, and an example of one type of bearing that is used across numerous industries and applications is the pillow block bearing (referred to sometimes as a Plummer block bearing).

Pillow block bearings are very adaptable and can accommodate dozens of different applications and shaft sizes with moderate-to-heavy loads. Pillow block bearings are used in numerous industry types including manufacturing, automotive, agriculture, mining, construction, and food processing. The design and availability of pillow block bearings makes them a vital component of the practice of mechanical engineering.

What is a Pillow Block Bearing?

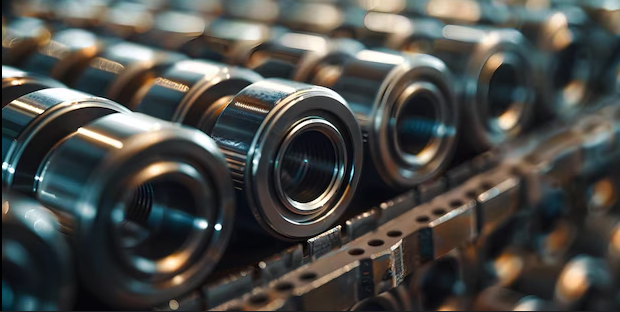

A pillow block bearing is a kind of mounted bearing and provides support for a rotating shaft and ensures it is aligned properly while rotating. A pillow block bearing has two main parts: the bearing inserts and the housing block. The bearing insert is generally spherical or self-aligning to allow for some shaft misalignment. The housing block is usually made out of cast iron, steel or thermoplastics and fastens the bearing to a mounting surface.

This setup provides for stable, low-friction rotation whilst accommodating radial loads and some axial loads. Most pillow block bearings come pre-lubricated and sealed, so they are self-lubricated for long wear and low maintenance in a wide variety of industrial applications.

Types of Pillow Block Bearings

Pillow block bearings also come in many designs and sizes to fulfil the different applications required for the industrial and commercial industry. Standard pillow blocks can be used for many applications with nominal and wide shaft size issues; split pillow blocks can serve heavy-duty usage and provide a split housing which may assist installation and maintenance; thermoplastic pillow blocks are a popular application for the food and pharmaceutical industry as they provide corrosion resistant properties, and stainless-steel pillow blocks used in washdown applications and extreme humidity. supplied.!

Depending on the application requirements, all of these housings are used for different bearing inserts: deep groove ball bearing, spherical roller bearing, or tapered roller bearing. Depending on the required performance or load capabilities, manufacturers have options available for each type of bearing insert.

Working Principle

A pillow block bearing works on the principle of limiting friction between a rotating shaft and a stationary support. The pillow block includes a spherical bearing insert in a cavity in it which allows low-friction points for the shaft to rotate without binding and allows it to be aligned.

The insert will self-align, allowing for minor installation errors or shaft deflections. Because the housing block is firmly fixed to a base, the stability of the pillow block also provides a more effective transfer of load which will help to minimize wear on the machinery and vibration in the working system.

Applications of Pillow Block Bearings

Pillow block bearings are an excellent choice for a diverse set of applications across many industries because they are robust, effective, and simple to maintain. They are well-suited for a wide variety of industrial uses. One example of a situation in which pillow block bearings are used is in a conveyor system, where the rollers provide support for items going from point A to point B while staying aligned.

There are thousands of conveyor systems running in factories, warehouses, and airports that rely on smooth-free material movement with pillow block bearings. In an agricultural scheme – like a harvester or tiller – collapse with dust, vibration, and heavy load makes pillow block bearings applicable in difficult outdoor conditions. In the food processing sector, food-grade types are constructed of thermoplastic and/or stainless steel to ensure sanitary conditions and to resist corrosion. Pillow block bearings are used widely in the textile industry to support the rotating shafts and rollers in a loom or spinning machine.

Pillow block bearings are important in HVAC systems to support the fan shafts and play an important role in providing a continuous flow of air without vibration. The construction industry also relies on pillow blocks. They are commonly found in mixers, pumps, and conveyors that require robust support in unfriendly environments.

Advantages of Pillow Block Bearings

Pillow block bearings are utilized across many industries because they are durable, versatile, and low maintenance. In a conveyor system, they stabilize the alignment and allow for the rotation of a roller to ensure smooth material handling in warehouses, factories, airports, etc. In agricultural machines, such as harvesters, unties, or other types of farm machinery with moving parts, they have the durability to withstand dust and vibration while carrying a heavy load for outdoor conditions.

Food processing equipment utilizes pillow block bearings because of their hygienic and corrosion resistance properties using thermoplastics and stainless steel variants. In the textile industry, pillow block bearings allow for the rolling and appropriate shaft rotation functions of looms and spinning machines. In HVAC systems, pillow block bearings are able to help support the fan shaft to allow for continuous, uninterrupted, air movement without vibrations. In construction equipment, they are seen in mixers, pumps, and conveyors giving support in harsh conditions similar to the food and agricultural industries.

Manufacturing Process of Pillow Block Bearings

Pillow block bearings are produced through a careful, precision-controlled process to achieve high performance, longevity, and dependable operation in applications. The first step is material selection, in which sturdy materials in the casting, such as cast iron or stainless steel, are chosen for the pillow block bearing housing, while premium quality alloy steel (which is usually heat treated) is used for the bearing insert. Once the materials are chosen, the housing and inserts are produced using CNC (computer numeric control), machining and forging methods to achieve precise tolerances with the specified features.

The housing is milled and drilled so it has mounted holes and any internal features as specified; then insert receives heat treatment for improved wear characteristics, with the finish grinding, polishing and ultimately presence of smooth surfaces trading off expensive process time with end use tolerances. Next, during assembly, the insert is fitted into the housing. sealed using optional (where specified) seals, and grease lubrication or end caps as needed. Each bearing assembly is then subjected to quality control checks using procedures that include physical load tests and vibration analysis once more after completion assembly.

Quality assurance checklists along with measuring and dimensional inspections create the best portion of load test comparative average “skew” if they all pass to verify the testing will be consistently reliable in practical end uses in each application.

Pillow Block Bearings in India

With its strong manufacturing ecosystem and deep engineering capability, India is already a major global supplier of pillow block bearings. Indian manufacturers supply many standard and custom solutions to both domestic and international clients, addressing the wide variety of end markets. The strengths of Indian manufacturers include touring innovations in CNC machining, automated assembly lines, and tons of knowledge in international standards as they follow ISO, AMS, AISI, and other standards.

They also have competitive prices, strong logistics and export players, and R&D in housing capabilities. As the industrial sector in India continues to grow, and automation in machinery continues to evolve, it is safe to say that India is poised for a bigger role in the international pillow block bearing supply chain.

Factors Affecting Performance

There are several major factors that affect the performance and failure of pillow block bearings. To ensure proper handling and maintenance of pillow block bearings recreationally, it is important to recognize several contributing factors to failure. The first factor is alignment. If your pillow block bearings are misaligned, then the load is not evenly distributed. This can cause increased wear and failure of the bearing in a significantly shorter amount of time. The second factor is lubrication. When properly maintained, lubrication reduces friction and heat; therefore, lubrication must be properly maintained. The third factor is loading limits.

Taking loads beyond limits can permanently deform bearings and reduce the service life. The fourth factor is contamination. Contamination can include dirt, solids, water, and some chemicals that can enter the pillow block bearings. The fifth factor is installation. By properly installing the shaft and mounting pillow block bearings, you avoid the possibility of vibration and instability of the bearings. Performing regular inspection and associated maintenance finds evidence of degradation and failures that could become catastrophic.

As a result, due to conditional changes, pillow block bearings should be monitored more frequently. But it is prudent to adhere to a yearly schedule. Overall, with a proper inspection and maintenance program you can usually catch critical failures much earlier. You can also help you improve through-put reliability and service life in any pillow block bearing application.

Conclusion

Pillow block bearings can be found in a wide variety of mechanical systems, and they remain the longtime reliable method to support the rotating shaft. The simple installation, versatility and ability to run for years, make pillow block bearings the first choice in many industries. Pillow block bearings have come a long way, with all the improvements in materials technology, manufacturing processes, and design options that made for better performance, longer operating and service life.

In assessing the correct pillow block bearing and the right supplier, operators from small to large machine applications should recognize the importance of product reliability, operational efficiency and proven design and engineering experience.

As manufacturing nations like India continue to produce affordable, high-quality pillow block bearing solutions thickness there will be a steady growth of demand for pillow block bearings for many years.