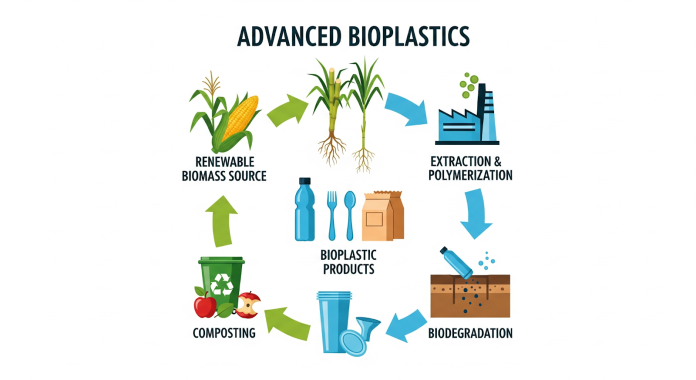

Advanced bioplastics are made from renewable materials such as starch, cellulose, and algae and are intended to be of longer life, more flexible, and more heat resistant as compared to traditional bioplastics. The main factors to which these companies can attribute their increase in market growth are the growing concern for the environment, more stringent government regulations, an increasing consumer demand for sustainable products, and technological progress in biotechnology and materials science, which facilitates their use in the packaging, automotive, agriculture, and healthcare sectors.

Key Growth Drivers and Opportunities

Rising Global Concerns over Plastic Pollution: The advanced bioplastics market is expanding as the administrations, corporations, and users look for environmentally friendly substitutes to fight plastic pollution. The need for ecological, bio-degradable, and recyclable materials has been steadily increasing, and advanced bioplastics are providing a viable solution that not only allows companies to comply with the regulations but also helps them accomplish their sustainability objectives and attract the loyalty of green consumers.

Challenges

Some of the restrictions looking into the advanced bioplastics market include the high cost of their manufacturing as compared to the conventional plastics, limited capacity for large-scale production, difficulties in achieving uniform product performance over a wide range of applications, and fragmental recycling infrastructure which are all responsible for the slow spread of their usage despite a strong demand.

Innovation and Expansion

Researchers Use Sophisticated Bioengineering Techniques to Create Polymers Derived from Sustainable Biomaterials

In August 2025, Plastic items usually wind up in landfills or pour into natural environments, taking up space and endangering species. To address this issue, the US National Science Foundation (NSF) has provided funds to a team of academic and industry researchers to create processes for producing durable and reusable bioplastics. In addition to their environmental benefits, bioplastics derived from local raw materials may serve to enhance US supply chains and industry.

The enzymes created by this research initiative will be as tough and malleable as the plastics that presently dominate the market. Rather than depending on petroleum-based chemicals, these new bioplastics polyhydroxyalkanoates (PHAs) would be made from locally produced feedstocks including corn, sugar, and agricultural waste.

Emirates Biotech Begins its PLA Bioplastics Company in Dubai

In July 2024, SS Royal Kit Emirates Investment and Global Biopolymers Industries have joined forces to establish a new venture to transform the PLA bioplastics industry. The company, Emirates Biotech, will spearhead the production and marketing of PLA biopolymers across the Middle East, Africa, and India, offering a sustainable and circular solution to replace traditional fossil fuel-based plastics.

Emirates Biotech will start commercial operations in early 2025 and intends to start construction of its first PLA production plant in the UAE before 2026.

Inventive Sparks, Expanding Markets

R&D, collaborations with significant industries, the growth of capacity, the use of environmentally friendly raw materials, and the employment of circular economy principles are the main priorities of companies producing advanced bioplastics, who besides that are also expanding their reach through mergers, acquisitions, and cross-border partnerships.

About Author:

Prophecy is a specialized market research, analytics, marketing and business strategy, and solutions company that offer strategic and tactical support to clients for making well-informed business decisions and to identify and achieve high value opportunities in the target business area. Also, we help our client to address business challenges and provide best possible solutions to overcome them and transform their business.